We specialise in the manufacture of step-lap mitre cores from small distribution to large power cores.

Mitred cores built to your specific requirements ranging from 5kVA to 80MVA. Cores are mitred from specialised Grain Orientated Electrical Steel Strips. This is critical in order to meet the demand of low losses that Electrical Utilities demand.

Latest

technology

We pride ourselves with keeping in touch with the latest materials and technologies.

Tested and

Guaranteed

All material is tested before manufacture with our in-house Soken Iron loss tester.

Highest

Quality

We deliver quality cores with quick turnaround times at fair prices.

Products

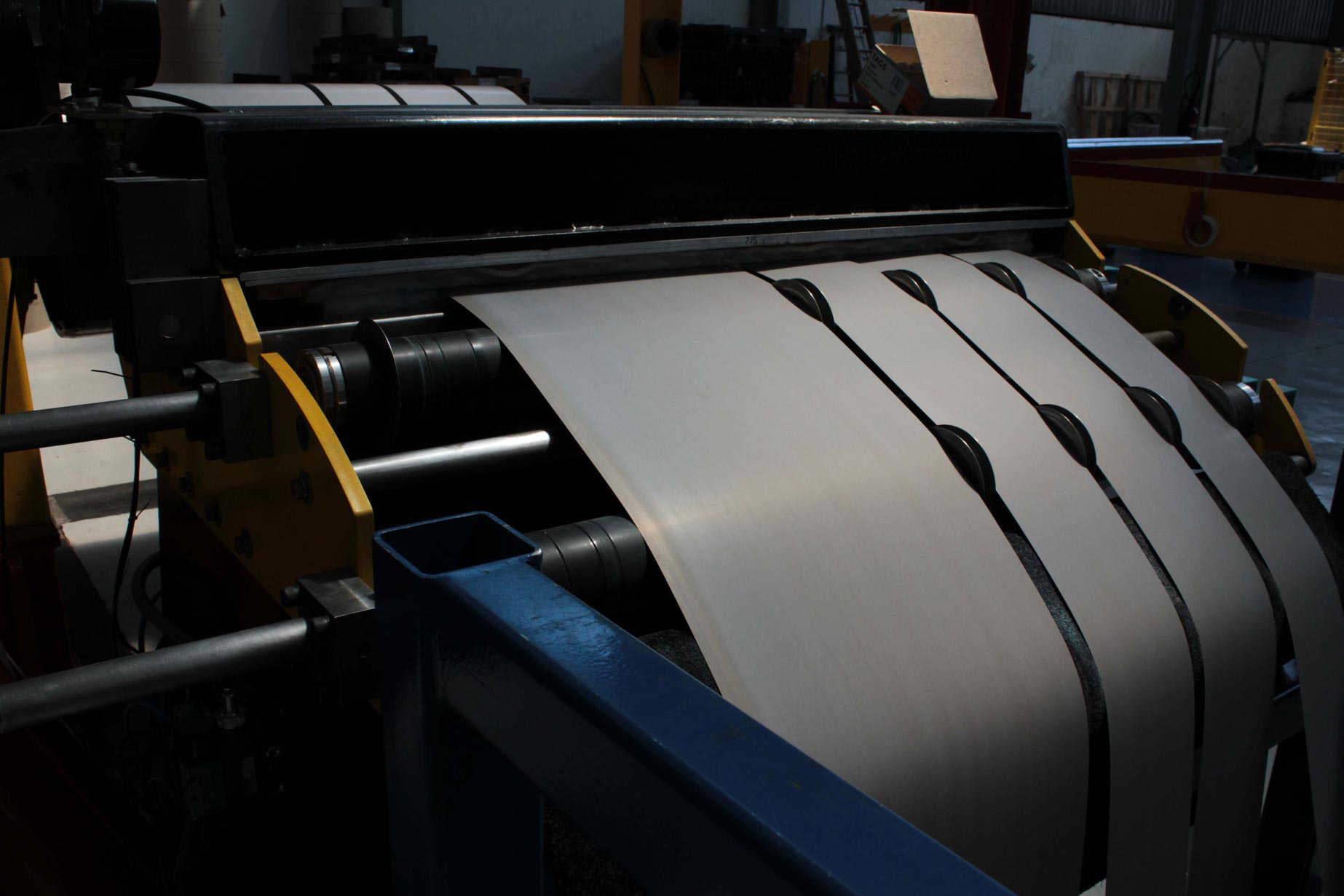

Slitting

lines

MCT slits wide coils from 1.2m to 40mm strips and from 600mm to 10mm strips.

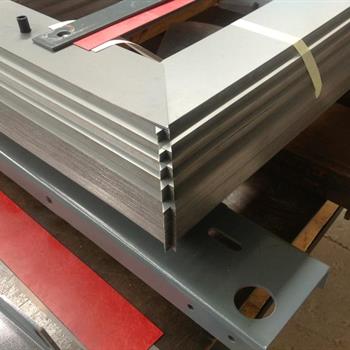

Mitering

Machines

We craft mitred cores tailored to the unique specifications of our customers.

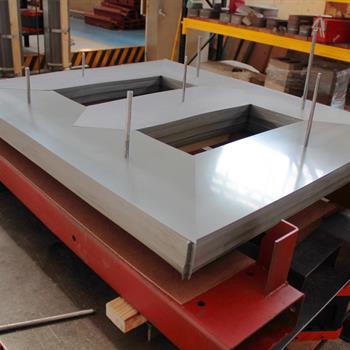

Core Assembly

Mitred Laminations

Mitre cores are manufactured as vertical or horizontal Step-Lap. Our preferred strip widths are from 40mm to 600mm in increments of 10mm.

As a standard, a 10.3mm hole is punched in the laminations for stacking accuracy. Available punch sizes are: 8, 10.3, 13, 18, 24 and 32mm diameter. We are able to punch holes in the Yokes and Limbs. Any other hole size available on request.

We can produce step-lap cores to various configurations based on customer designs.

We manufacture flat or round Yokes as well as oval or round Limbs as per customer requirements.

Our standard displacement for cores under 160kVA is10mm (5/5). For cores greater that 160kVA the standard displacement is 20mm (10/10). Cores can be supplied cut and stacked or cut and packed as per customer specification.

Testing Facilities

Our specialised mitred cores and Step-Lap cores are made from the best Grain Orientated Electrical Steels available. Each core is guaranteed and comes with a comprehensive test certificate showing actual no-load losses as well as dimensional specifications.

All material is tested before manufacture with our in-house Soken Iron loss tester.

These test results are compared to the mill test certificates to ensure quality and authenticity of material used.

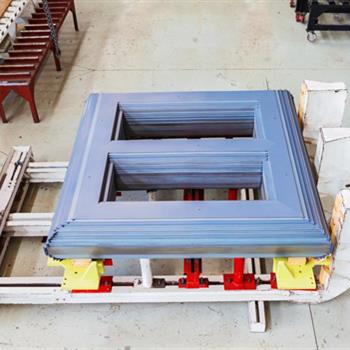

Core Clamps

We employ experienced professionals in core clamp production to tailor each product to the customer's specifications provided in thier drawings.

AMC Group of companies

Whatever your requirements, we can manufacture.